Day 1

Ground floor elements installed

Working in collaboration with H+H we developed the award-winning i-House concept.

Our collaboration with H+H means we can offer a complete watertight shell of a standard house design in just one week.

Our i-House product combines the speed and quality of off-site construction with the familiar and trusted characteristics of masonry build.

We recognised there was a demand to increase the volume within the house building industry when skilled workers were in short supply. Working with H+H, we were able to design and produce an innovative solution.

The defining feature of i-House is the storey-high panels of aircrete that form the structure of the external cavity and internal separating walls. Prefabricated offsite, these Vertical Wall Panels are lowered onto the foundations by crane and fixed with ultra-strong mortar.

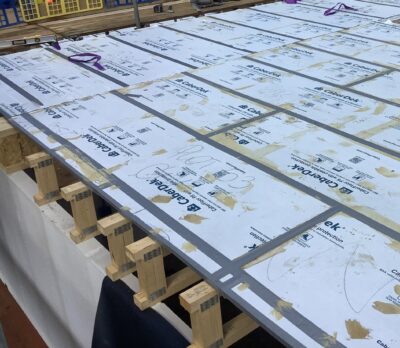

Combined with prefabricated timber floors and topped with i-Roof the i-House solution is wrapped in insulation ready for the follow-on trades. The entire fabric of a standard house type can be completed in just one week using the Roofspace specialist installation team.

Vertical Wall Panels benefit from the thermal efficiency of aircrete while the thin mortar joints give exceptional air tightness. An ideal solution for high-performance housing designs such as Passivhaus.

Intended for domestic property construction up to three storeys, i-House consists of inner leaves of external cavity walls, separating walls, floors, lintels, cavity closures, insulation and roof trusses with the inclusion of soffit and fascia for the internal skin of the property which is then fully wrapped and ready for follow-on trades. i-House can be combined with i-Roof, or can be fitted with traditional roof trusses.

Prefabricated homes are built off-site in controlled environments, allowing for faster assembly and reduced project timelines.

The time savings are compounded as the interior trades can start work as soon as the fabric is completed, working simultaneously with external brickwork contractors, further reducing site time.

The efficiency of factory production allows for houses to be assembled a lot quicker, which in turn reduces labour costs.

This, along with the reduction in waste materials, can lead to impressive cost savings.

With precise manufacturing processes in a controlled factory environment, material waste is significantly reduced.

This is because a factory setting allows for exact measurements, allowing for a more efficient use of materials.

The way in which our modular houses are manufactured allows for precision and consistency.

We also quality control each and every iHouse that leaves the factory, ensuring each section is manufactured to perfection.

The large scale H+H Celcon Elements are manufactured from the same intrinsic material as aircrete blocks with the same performance advantages including excellent thermal performance with reduced heat loss at thermal bridges. Our experienced team will run the project from start to the delivery of the wrapped structure, allowing you to focus on other areas of your project, and the management of the follow on trades.

Our experienced team will run the project from the original designs to the completion of the fully-wrapped structure.

Ground floor elements installed

Floor cassettes and block infill completed

First floor elements installed

Wall plates are added

Roof trusses installed and build complete

Our Contracts Managers offer full support throughout the process including after care once the installation has taken place. During the install, you will have a team of four operatives on-site, including a slinger signaller, crane supervisor and a fully competent crane operator.

As well as full support right from your initial enquiry through to after care and the team on-site throughout the installation, we also provide a crane on-site, two floors of floor cassettes, party wall insulation and of course the H+H element blocks.

Yes, our i-House and i-Roof solutions are fully compatible with each other, speeding up the build time even further.

When working with existing customers and their standard house types, we require six weeks. When we welcome a new customer on-board, it can take longer as we need to create their house type designs, however, once these are set up, six weeks is all we need.

Absolutely, both of our solutions are approved by both our in-house design team and an external structural engineer, so you can rest assured the solutions we install on your sites are of the highest quality and workmanship every time.

Particularly suited to standard house designs for larger sites, i-House is ideal for planned social housing developments.

Simply fill in the form and one of our construction experts will get back to you within 48 hours.